compression test does not hold pressure|Why Hold the Throttle Open During a Compression : factory Your compression gauge could be defective because it is not holding a peak pressure reading. However, because the engine is running very poorly, I suspect that you . Resultado da XVideos.com is a free hosting service for porn videos. We convert your files to various formats. You can grab our 'embed code' to display any video on .

{plog:ftitle_list}

Resultado da Busty MILF Natasha Nice Takes Her Cute Stepson's Anal Virginity! French Subtitles. 15 min MommysBoy - 3.3M Views -. 1080p. HOT HORNY BABE at the HOTEL:SUBMISSIVE SECRETARY BEGS her BOSS for her Promotion.He ROUGH FUCKS HER TIGHT JUICY PUSSY,POWER .

I am trying to check the compression on my Stihl BR420c blower. My compression gauge does have the schrader valve in hose. After about four pulls the compression builds up to about 125 psi but immediately start dropping down.

UNIVERSAL TENSILE TESTER warehouse

Almost every compression testing guide tells you to hold the engine’s throttle wide open during a compression test, but most won’t tell you why it may (or may not) matter. What's a Throttle? On gasoline engines, the . A compression test measures a cylinder’s ability to hold pressure as the piston moves up and down. Mechanics use an oscilloscope and observe the stored pattern as the . Your compression gauge could be defective because it is not holding a peak pressure reading. However, because the engine is running very poorly, I suspect that you .

Next, attach the leak down tester to your air compressor and then slowly turn the air up to 100psi. If you do not have a compression tester, you can use this tool as a cheater for that as well. If the cylinder pressure is at least .Jul 19, 2016 These types of numbers indicate that the cylinder is not holding compression efficiently. Look for issues such as slightly bent or burned valves, excessive carbon build-up on valves or seats, .

This tutorial will teach you everything you need to know to do a compression test on any engine. I cover the process from start to finish including what comp.

The premise of a compression test is to test each cylinder to see in measured PSI exactly how much compression that particular cylinder is producing. From a single piston lawn mower engine, to a diesel or V8 engine, the process is .

2. Add Some Oil to the Cylinder with Low Compression. If there’s low compression on one cylinder, you can put some oil into it and retest. If higher pressure occurs after putting oil into the cylinder, you know where the .

1. Compression tester - I believe you have compression gauge that does not have the required Schrader valve in the tip. If it doesn't, it won't work right. First, the hose then increases the effective combustion chamber .In Example 1, cylinder #1 has a snap test reading that is much lower than the other cylinders. If a snap reading is low (much less than 80% cranking compression), look for air intake problems such as severe carbon deposits on intake valves, worn cam lobe,worn valve guides and springs, rocker or push rod problems, or "shutter valve" miss-positioned in the runners of a variable . In my opinion, you should NEVER do a a running dynamic compression test. Unless you understand why you are doing that test. As well as, what you will do with the results. A running dynamic compression test, can also be used to pinpoint, the cause of a misfire. Subsequently, even when all the usual tests, return normal results.

The pump does not turn off when the tank’s pressure exceeds the preset cut-off pressure. The pump does not turn on when the tank’s pressure drops below the preset cut-on pressure. The pump short cycles. The pump is running, but the water pressure in your home is low. A short-cycling pump and low water pressure may be caused by a ruptured . So, if your engine is running rough or is lacking power, consider doing a compression test. Also, it is important to perform a compression test every time a tune-up is done, as part of preventative maintenance. You really don’t need special skills, to do a compression test. But, you do need to know, how to understand your results properly.

Some buyers say the o-ring meant to seal to the spark plug hole does not hold pressure, adapters are too large to reach the spark plug holes in some vehicles 4. JIFETOR Compression Tester Kit We now know the misfire is due to a lack of compression and not a faulty ignition coil or fuel injector. You have done the initial steps to . You will need a helper to hold the crankshaft with a breaker bar as you do the test. The pressure isn’t insane, but it is enough to hurt you badly if a finger or arm is in the wrong place at the wrong .The cylinder leak down test allows DIYers and professionals to assess the integrity of an engine’s internal components. This test, indispensable for measuring the capability of an engine to hold pressure, is an integral part of any thorough engine health assessment due to its ability to pinpoint issues that rob you of power and reliability. A compression test will reveal the state of your engine’s parts, and can potentially save you money on buying a replacement engine. . This disables the ignition system and fuel delivery system, which ensures the engine does not ignite during the test. Disconnect spark plug wires. . As for the Oil Pressure Light, you may have a blockage in .

I second the try a new compression tester suggestion. I was helping a buddy check his compression and his gauge did not hold pressure either. No problem holding the reading with a new gauge. What casting numbers are those Power Heads? Hope they are E7s. Large chambers will lower your compression ratio.

If you want to find a coolant leak or test the pressure of the cooling system after a coolant flush, you can perform a radiator pressure test, also known as a coolant pressure test. The test requires connecting the pressure tester to the coolant reservoir or the radiator and pumping the tester to pressurize the system, which can help find coolant leaks.

Why Hold the Throttle Open During a Compression

So i tried doing a compression test today. i was having the same problem with two testers. The first one i screwed in, the needle would bounce as i cranked the engine but it would not "hold" the pressure. I made sure it was good and "hand tight" in the spark plug hole. I went and got a second tester, a "loner" from advanced auto. I've heard of a compression test that measures how effectively each cylinder will hold pressure. Q1: Is that enough of a proxy to ensure there isn't gunk build up (i.e. if there isn't excessive wear on the rings then they've probably changed the oil frequently enough to avoid blockage due to old oil build up. So, a reading of 8-10% on a newer engine is great. Up to 20%, even 25%, on an engine with some wear can still function well if the engine also has good cranking compression readings. On an engine with 20%-25% or .

Crank the Engine: Have an assistant crank the engine by turning the key in the ignition while you observe the gauge.Allow the engine to crank for about 5-10 seconds or until the gauge needle stabilizes at its highest reading. . So during a check I noticed that my compression tester isn't holding pressure anymore. Just about gave me a god damn heart attack when I put it on a different cylinder only to see it go up and then go down. I verified it was the tester not working by putting it back on a good cylinder only to see the tester shoot up and drop down to zero.If it has to be held in place, hold it firmly to avoid leaks. Tell your helper to crank the engine for at least ten revolutions, or about six to eight seconds. Take care that loose clothing or hair does not get caught in belts or pulleys. The pressure reading on the gauge.increases in steps, and may take up to ten revolutions to reach a maximum. 2. Can I perform a compression test myself, or should I seek professional help? You can perform a compression test yourself with the right tools and guidance. However, if you're unsure or encounter significant issues, consulting a professional mechanic is advisable. 3. What should I do if the compression levels are low in one or more cylinders?

A compression test measures the pressure in each engine cylinder to assess health and performance. Good compression ranges from 120 to 200 psi with minimal variation between cylinders. . If the pressure does not improve with the wet test, the issue may lie with the valves. A leak-down test can further pinpoint whether the valves are leaking.

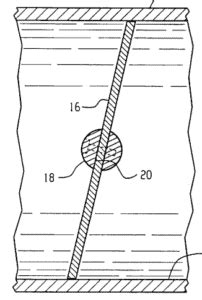

Compression tests are performed to characterize the behavior of a material under compressive loading.; During the test, pressure is applied to a specimen using compression platens or special tools mounted on a universal testing machine to determine various properties of the material being tested.; The test data delivers results in the form of a stress-strain diagram that . Leak down Test and Compression Test (as they apply to the 4stroke DRZ) These two diagnostic procedures are often confused, misused, and why faulty data results. . There are other ways to hold the engine at TDC, from adapters that both feed compressed air into the cylinder and act as a piston stop, to holding the crank in place by the primary .

Carry Out a Compression Test. To find out which cylinders have low compression, you’ll need to carry out a compression test. You’ll need a compression gauge, some tools, and a little mechanical knowledge to do this. Step 1. Remove the fuel pump and fuel injector fuses. This stops the engine from injecting fuel into the cylinders when . Remove the injector hold down clamps discard the hold down bolt and remove the compression test adaptors from the cylinder head. 26. Using new sealing rings and injector hold down bolt install the injectors back into the cylinder head and torque to specifications; Torque bolt to 50 Nm (37 lb ft) Loosen the bolt 60 degrees ( 1/6 of a turn or one .

In this DIY Tech Tip from Lowbrow Customs, Todd shows you how to test your motorcycle's cylinder compression, and what it means. A simple compression tester which is available at most any auto parts store is all that is needed for this useful task. This can help identify compression loss, which has a MAJOR effect on the engine's power, due to worn .Study with Quizlet and memorize flashcards containing terms like Which of the following would indicate a general weak-engine condition when operated with a fixed-pitch propeller or test club?, By use of a differential pressure compression tester, it is determined that the No. 3 cylinder of a nine-cylinder radial engine will not hold pressure after the crankshaft has been rotated 260° .

The basics of a proper compression test require a full and unrestricted flow of air to the cylinder, and enough compression strokes to build to maximum pressure. Test results will fall into the acceptable psi/kPa range, and each cylinder should .

The CORRECT Way To Do A Compression Test

WEBCarregando. .

compression test does not hold pressure|Why Hold the Throttle Open During a Compression